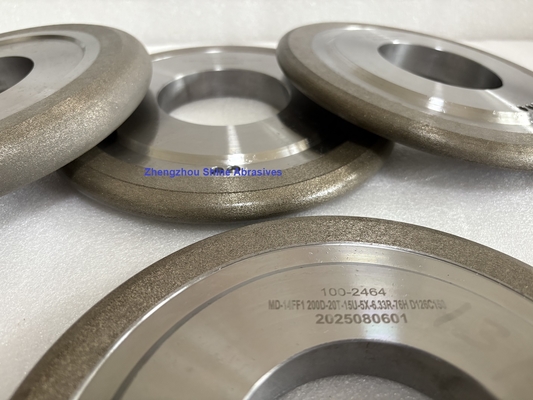

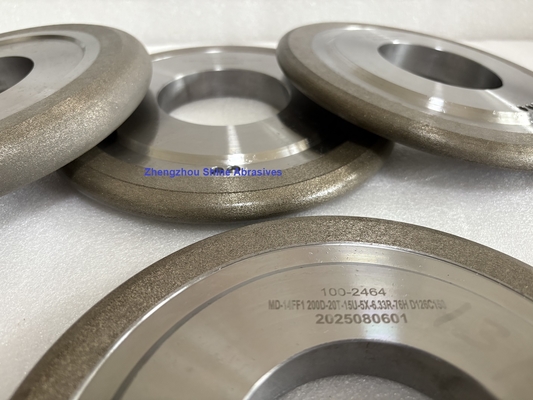

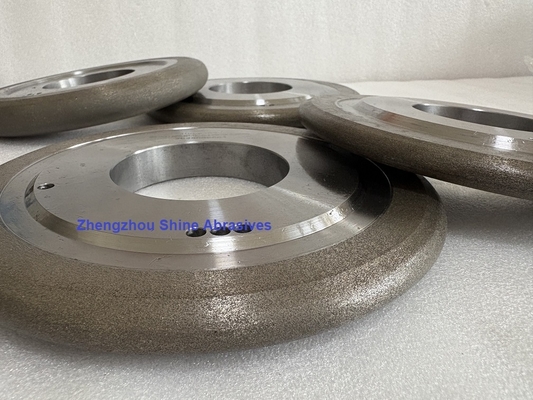

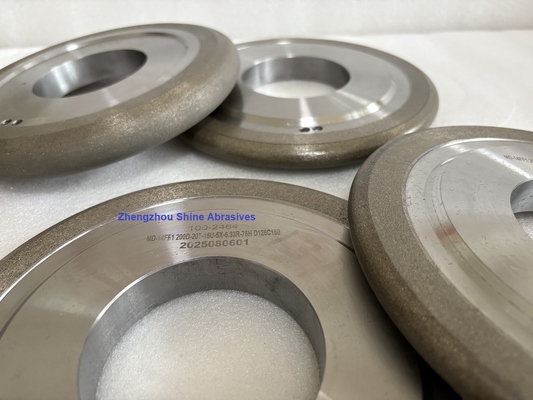

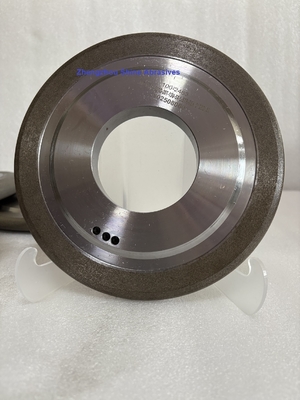

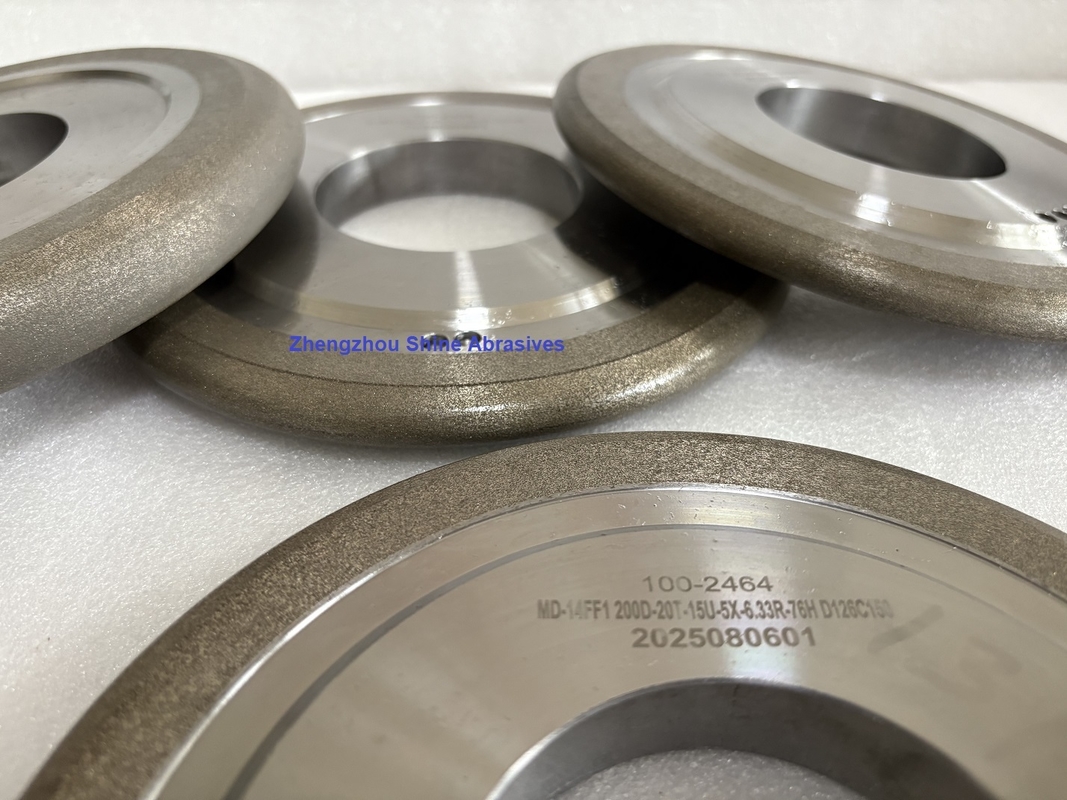

200mm 14F1 metal bond diamond wheel for carbide roll grinding or profile.

Wheel picture:

wheel dawing:

Overview:

Metal bond diamond wheels are specifically designed for grinding hard materials, including carbide rolls. These wheels use a metal matrix to securely hold diamond abrasives, providing durability and stability during grinding operations.

Key Features:

Metal Bonding:

The metal bond provides a strong and rigid structure that enhances the wheel's durability, making it suitable for high-stress grinding applications.

Diamond Abrasives:

Embedded with high-quality diamond particles, these wheels offer excellent cutting performance on hard materials like carbide.

Grit Sizes:

Available in various grit sizes, allowing for different grinding applications, from rough grinding to fine finishing.

Applications:

Grinding Carbide Rolls:

Ideal for precision grinding of carbide rolls used in various industrial applications, such as metalworking and manufacturing.

Tool Sharpening:

Used for sharpening cutting tools made from carbide, ensuring optimal performance.

Surface Finishing:

Effective in achieving a smooth surface finish on carbide components, which is critical in many applications.

Manufacturing of Cutting Tools:

Employed in the production of carbide cutting tools, enhancing their performance and longevity.

Advantages:

High Durability:

Metal bond wheels have a longer lifespan compared to resin or vitrified bond wheels, making them cost-effective over time.

Excellent Cutting Efficiency:

The diamond abrasives provide superior cutting capabilities, allowing for fast material removal from hard carbide surfaces.

Reduced Wheel Wear:

The strong bond helps minimize wheel wear, maintaining the wheel's shape and profile for consistent performance.

Good Surface Finish:

Capable of achieving high-quality surface finishes, reducing the need for additional finishing operations.

Stability Under Pressure:

The rigid structure of metal bond wheels allows for stable grinding, even under high pressure, resulting in better control and precision.

Versatility:

Suitable for various grinding applications beyond carbide, including ceramics and other hard materials.

Conclusion

Metal bond diamond wheels are highly effective for grinding carbide rolls and other hard materials. Their durability, cutting efficiency, and ability to produce excellent surface finishes make them a preferred choice in industrial applications. Proper use and maintenance will further enhance their performance and longevity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!