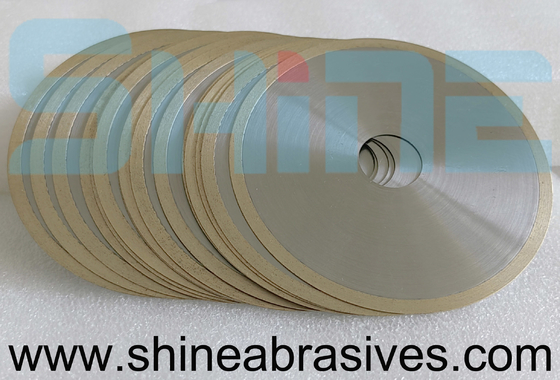

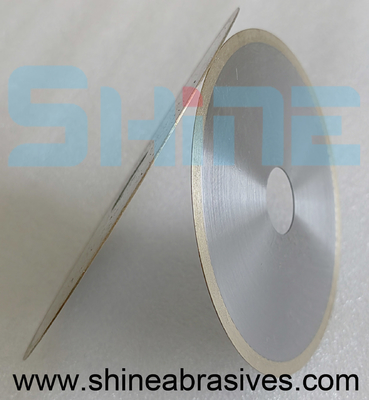

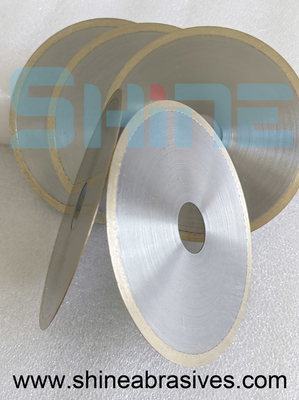

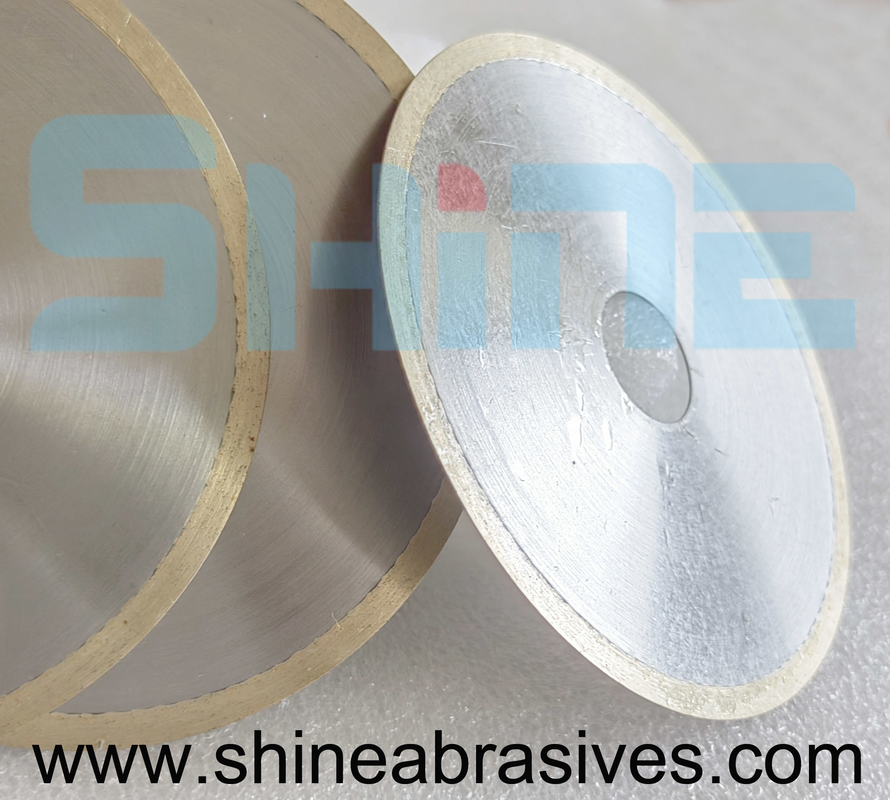

Shine Abrasives 1A1R for cutting carbide and high-speed steel

CBN wheels are graded by the hardness of the bond. A higher-hardness bond allows for longer wheel life when compared to conventional wheels, such as aluminum oxide and silicon carbide.

To determine the hardness of a wheel, one must first understand how the abrasive grit works.

A wheel is considered soft if the abrasive grit fractures or pulls out from the bond easily. A wheel is considered hard when the abrasive grit is held into the bond firmly, and does not result in microfracture.

Typically, if the working material is easy to cut, a high-hardness wheel is suggested. A softer wheel is used for a more difficult to grind materials, such as sub micro-grain TCT cutting tools.

Our vacuum brazed diamond wheels are used for grinding, stock removal, and beveling in a wide variety of industries like metal processing, automotive, aerospace, ceramics, and composites.

What is a vacuum-brazed wheel?

Vacuum-brazed wheels contain a single layer of super abrasive grit that is bonded to the core with a proprietary alloy mixture that is melted around the abrasive grit and cooled to lock the abrasive grit in place. An extremely blocky diamond grit is used because vacuum brazed wheels are typically used in processes that require high durability.

Grit sizes range from D20/30 to D80, allowing for a large portion of the grit to be exposed. This allows for extremely aggressive grinding.

Our 1A1R diamond grinding wheel features man-made diamond, more consistent in shape than natural diamond, for sharp, even cutting action, durability and long life. Resin-bonded to produce a self-sharpening effect and even grit distribution. Can be used wet or dry on carbide, ceramic, glass, welds, quartz and other hard, brittle and short chipping materials. 150 grit / 100 concentration. Measures 6" in diameter, has an arbor hole of 1-1/4" and the grinding surface measures 0.035"" while the diamond depth is 0.028".

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!