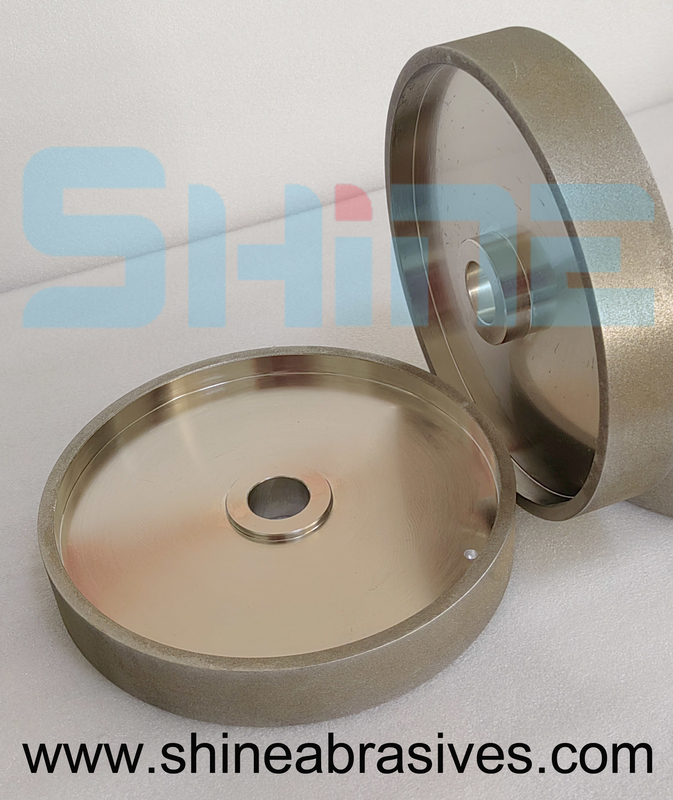

Electroplated diamond or CBN abrasive & Resin Bond diamond or CBN abrasive

Abrasive tools using diamond or CBN abrasive grains generally include a matrix, and the grinding layer composed of abrasive grains and bonding agents is formed in different ways.

The abrasive particles and bond should be coordinated so that the abrasive particles are fixed in the bond while still having or capable of forming a cutting edge, thus adhering to the substrate. Get ideal grinding performance. If worn abrasive grains remain in the bond for too long, the abrasive tool will lose efficiency. On the contrary, if the bond wears before the abrasive grains, or it cannot be fixed for a long enough time, the abrasive grains will not be fully utilized, and the service life of the abrasive tool will be shortened, making it uneconomical.

Adopting a suitable consolidation structure for each special application and effectively utilizing the abrasive material can achieve ideal efficiency. Therefore, it is of great significance to coordinate the combination of abrasive particles and binders according to the specific work and use conditions.

resin binder

·For grinding hard materials and steel

. High grinding efficiency under low grinding force conditions

Suitable for dry and wet grinding

. High flexibility due to mixing of appropriate additives

. Suitable for fine grinding process

metal bonding agent

. Has excellent wear resistance and shape retention. The force is large, so the grinding efficiency is lower compared to synthetic resin bonding agents.

hybrid bond has excellent cost performance and is used for grinding hard metals. The grinding parts feed speed is fast. The grinding wheel wear rate is low. Ideal trimming characteristics, EDM trimming possible

Ceramic Bond

. Used to produce grinding layers with defined porosity and has a very wide range of applications

. It has very good trimming and shaping properties and is particularly suitable for use

Diamond dressing set for adjustment

Low grinding wheel wear rate and low grinding force bring high-quality workpiece surface

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!